Food safety is vital, highlighting freshness, color, and spoilage prevention. Innovations in processing and transport enhance quality and preserve nutrition. Hot filling, Ambient filling, and Aseptic filling techniques maintain quality, appearance, taste, and extend shelf life. Aran provides customized packaging for various sectors using compatible bags, structures, and films.

Ensuring food safety and security is crucial in today’s world. To achieve this, it is important to focus on three main goals when distributing food: freshness, color, and avoiding spoilage. Freshness and color are essential indicators for consumers while avoiding spoilage is necessary to prevent potential health risks.

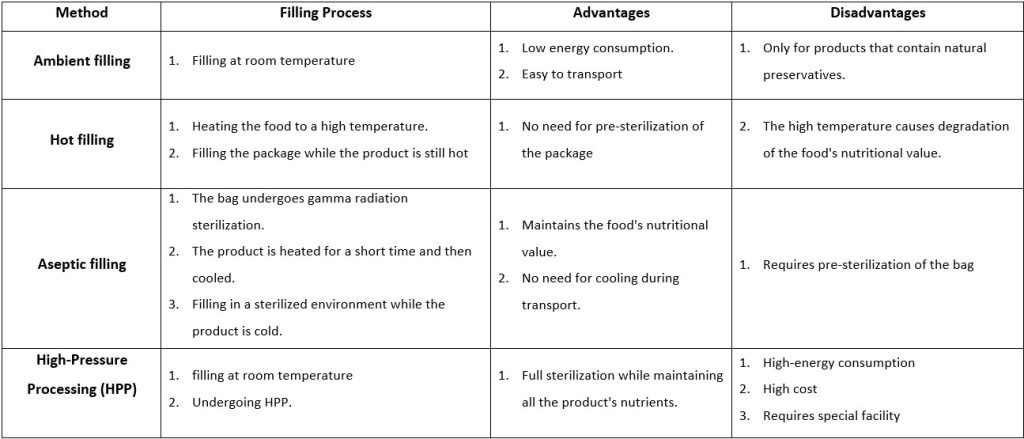

Food processing and transportation methods are key in maintaining both food safety and security. Continuous advancements in these areas aim to improve the overall quality of food products, preserving nutritional values and prolonging shelf life. Various methods, such as hot filling, ambient filling, and aseptic filling, can help preserve freshness and increase the shelf life of food items. Each method offers specific benefits that contribute to maintaining the quality and safety standards of the food. There are various packaging methods from rigid packaging made of metal, glass, or plastic to flexible packaging. Comparing the environmental impact of different packaging solutions shows that flexible packaging is a more sustainable and eco-friendly solution. Aran manufactures bags in box solutions, suitable for each of these methods and thus provides liquid packaging solutions to plenty of different sectors in the food industry.

Food Packaging Methods

Some food products are highly formulated with natural preservatives like salt, sugar, alcohol, or vinegar, making sterilization and chemical preservatives unnecessary. These products are packaged using Ambient filling at room temperature, a process that requires less energy and allows for efficient transportation. Aran’s bags are used for ambient filling of various products, such as wine, ketchup, post mix, and more, they arrive in a variety of sizes ranging from 3 liters to 20 liters, 55-gallon, and 300 gallon

Other foods require sterilization to keep up with the goal of food distribution, Hot filling or Aseptic filling is used to package them. Hot filling entails heating the food product to a high temperature before filling it into the bag, the heat from the product heats and sterilizes it, when the filling is done; the bag and content are cooled together quickly. One of the benefits of this method is that it eliminates the requirement for pre-sterilization treatment of the bag. However, a drawback of subjecting the food to high temperatures during this process is that it results in a reduction in nutritional value. Moreover, for some foods, such as tomato concentrate, the color of the product is adversely affected.

Aseptic filling is the most advanced and effective process method today. In this process, the food product is heated for a period, to a temperature that will sterilize it. Then it is cooled to approximately 10 Celsius. The fast cooling helps to maintain the food’s nutritional values, color, and freshness. At the same time, the bag undergoes radiation treatment, which thoroughly eradicates all microorganisms in the bag. The filling is done in a controlled sterilized environment. The advantage of aseptic filling is that it allows for a longer shelf life and does not require refrigeration while also preserving the color, flavor, and nutritional value of the food product. Aran’s flag products are aseptic bags in sizes ranging from 3 liters to 1000 liters, these are complex bags made of special formulations and Aran has all the knowledge and experience needed to manufacture them in high quality.

High-Pressure Processing (HPP)

Another food processing technology that is gaining popularity is high-pressure processing (HPP). This method uses high pressure to neutralize harmful bacteria, mold, and other contaminations while also increasing the shelf life of the products. It offers exceptional sterilization, making it an ideal choice. However, due to its high energy consumption and low production rate, HPP can be quite expensive. In this regard, Aran stands out as a reliable manufacturer of suitable bags for HPP. With their extensive experience and knowledge in the field, Aran is well equipped to produce co-extruded bags that effectively prevent flex cracks, ensuring optimal results for this innovative food processing method.

Bag Compatibility and Structure in Food Processing

The bags used in each method must be compatible with the process demands in terms of temperature resistance. Moreover, the structure of the bags and layers must fit the process and the products it stores Different film combinations to match the process. Each product is categorized for its need for a barrier and its acidity, the process and the bags are chosen accordingly. Aran can understand the process as a whole and listen to the customer In conclusion, food-processing technologies play a crucial role in ensuring food safety and security. The continuous development of these technologies has resulted in methods like hot filling, ambient filling, aseptic filling, and HPP that can help to keep food products fresh for longer and increase their shelf life. As technology advances, we can expect to see even more innovative methods for processing and transporting food products in the future.

Contributors to this article: Food Packaging Specialist Flavia Takahashi-Flores and Elhanan Hameiri.