The fruit and vegetable processing industry has unique requirements when it comes to packaging solutions. To address these specific needs, a specialized line of aseptic packaging solutions has been developed. These solutions are designed to store and transport liquid food products such as concentrates, pulps, and juices safely and efficiently.

The industry adheres to stringent requirements for hygiene, safety, and product quality. Aseptic packaging techniques play a crucial role in meeting these standards by preventing contamination, ensuring product freshness, and extending shelf life.

The fruit and vegetable processing industry can be confident that their products will arrive in excellent condition thanks to these customized packaging solutions. These solutions offer superior protection, ensuring that products remain safe during transport.

From 5 liters to 1000 liters a range of packaging solutions is available, providing flexibility in capacity and resistance to oxygen to meet customers’ specific needs and preferences.

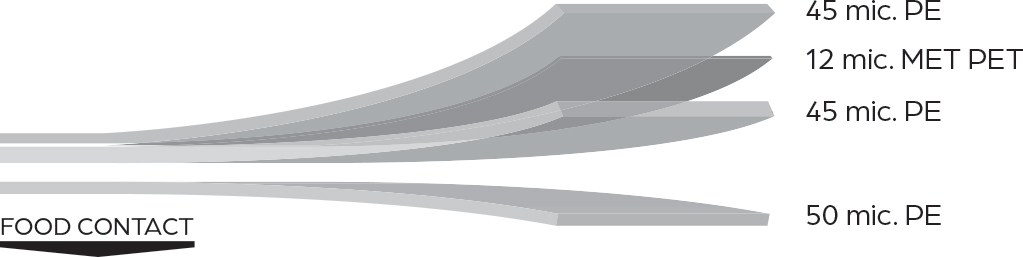

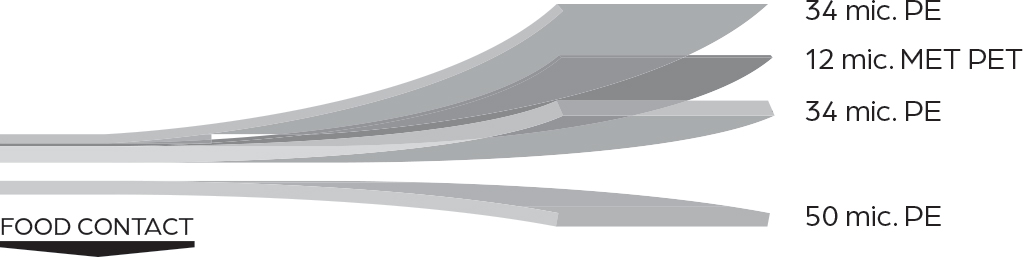

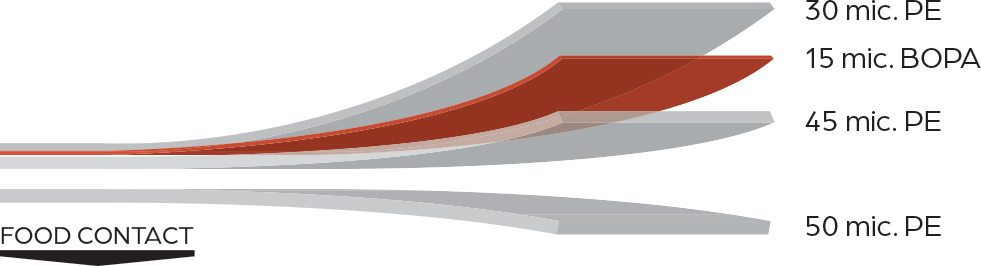

These packages are made from specialized laminate films that provide effective barriers against oxygen while remaining highly flexible.

To improve food distribution worldwide, Aran developed the SuperFlex and PremiumFlex series with improved mechanical properties that prevent flex cracks, allowing for longer transportation.

Compatible with various external packaging materials, including drums, wooden boxes, and plastic crates, these solutions offer seamless integration into existing supply chain processes.

Saving: An attractive economical solution for packing and transport of liquid foods in large quantities.

Convenience: An inclusive solution for the customer as a complete component within the IBC method

Transport: Convenient and efficient for the transport of large quantities long distances.

Protection: Highly resistant to perforation, and when needed can be aseptic with barrier features.

Environment: less pollution, due to a saving of 70% on raw materials.

Quality: The aseptic package goes through a special sterilization process, optimally protecting the packaged product in addition to maintaining varying degrees of oxygen barriers as required.

Flexibility: The flexible package is easy to use and protects the contents well.

Saving: An attractive economical solution to the packaging and transport of large quantities of liquid foods.

Adaptation: It is possible to combine all existing filling accessories on the market.

Transport: Easy and convenient to transport long distances.

Environment: Less pollution, due to a saving of 70% on raw materials compared to rigid containers of the same volume.

Bag-in-Box (BIB) presents itself as an innovative liquid packaging solution that offers numerous benefits to both the environment and our health. It guarantees the utmost safety and protection for food while being exceptionally eco-friendly. Aseptic BIB, in particular, stands out as a sustainable option, with a carbon footprint that is 60% to 80% smaller compared to conventional packaging solutions. This is made possible by its lightweight plastic laminates, which facilitate energy savings, reduced fuel consumption, and lower shipping costs.

Filling of the bags is done by designated machines adapted to the filling of liquid foods. The semi-automatic machine fills single bags manually, while the fully automatic machine has attached (perforated) bags that are automatically filled by the machine at high speed, with separation done upon completion of the process. The processing and filling process for aseptic B.I.B bags is done under sterile conditions to ensure product shelf life.

With manufacturing facilities strategically located worldwide, we offer personalized service to meet diverse market demands efficiently and sustainably

Customers can customize their product line with a range of spouts, hoses, and valves. Enjoy convenient fitments for easy product dispensing, supported by innovative filling processes to maintain product quality. Integration with all filling machines.

Aran Packaging

Tel: +972 54 8674681

Fax: +972 8 9278745

Dayan Schreiber

Email: dayan@aran.co.il

Address: Kibbutz Nachshon,

M.P. Shimshon, 99760, Israel

Tel. +34 983 56 1041

Fax. +34 983 56 0878

Noelia Berrocal Redondo

Sales Coordinator

Email: noelia@araneurope.com

Address: C/ Guarnicioneros, 4 Parcela 27 -CB

(P.I. San Cosme I) 47.620 – Villanubla, Spain

Tel: +972 54-757-5998

Dan Abraham

Managing Director

Email: dan.ab@aran.co.il

Address: Brägeler Ring 20, 49393 Lohne, Germany

Tel: +1 864 479 0023

Fax: +1 864-479-0031

Molly Goldenstar

Sales Coordinator

Email: mollyg@aran-us.com

Address: 1704 Poplar Drive Ext.

Greer, SC 29651, USA